Corporate Farming:

Corporate Farming:

We have undertaken several small farms and provided them with technology to boost their production speed and yield to make them more sustainable. Helping all small farms grow and providing them with the best price for their farmed products so that our overall yield is increased and more sales can be made. Also the quality of products coming from these farms is closely monitored to make sure it matches our own quality of yield.

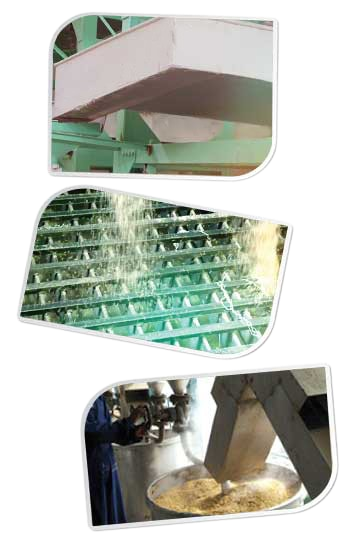

Husking Unit:

Husking Unit:

Each of our husking unit is capable of processing 250 metric ton/day output. Our trained & skilled labor carefully work on the processing units under strict rules and regulations from the Rice Development standard BS ISO 6646

STEAMING & PARBOILING UNIT:

Our rice steaming unit is engineered to perfection to maximize yield of head rice, minimize product breakage and deliver consistent product quality. Efficient hulling and separating performance with a focus on delivering maximum yield of head rice for optimal profitability.

The process of parboiling uses processed soft water obtained from water treatment plant. The plant has specially designed soaking bins with sensor based sophisticated controllers for water temperature.

The process is far superior than the conventional methods in terms of mitigating development of unwanted smells and ensures hygienic processing of the grain, preserving its fragrance and aroma during the processing. The requirements of soft water for parboiling process are met by an integrated water treatment plant.

Quality Control:

Quality Control:

You can trust our quality, We take care of quality and food safety from the root level. Ansons Foods assures the quality in three different stringent quality measures which include safety foods and quality management, quality from the harvest to table, per-harvest food safety and quality approaches. We have been ISO and Halal certified and also do treated water certification time by time that give us edge over other exporters of Pakistan as most of the people don’t know water is involved during rice process. We are within few of Pakistani exporters who are certified by CIQ to export to China. Our experienced quality control team which assures us 100% authenticity has earned us a name all over the world with the impeccable quality of products, high hygiene standards and on time deliveries with proper system to record humidity level during transit.

Research & Development:

Research & Development:

Our R&D facility was established and headed by Pakistan’s pre-eminent and award winning rice breeder and scientist (the late) Dr. Hassan former director of the Rice Research Institute at Kala Shah Kaku in Punjab. Recipient of the coveted Presidential Pride of Performance Award Dr. Zakir was inventor of Basmati 385 and extra-long grain Super Basmati varieties. The seed was multiplied and commercialized in 1990. This new variety of Basmati, now known as Super Basmati, MG Basmati gained wide acceptance among farmers and in the international market.

- A Pioneer Indigenous Company.

- Twenty eight years standing, one of the most experienced Seed Company in Pakistan almost as old as the industry itself.

- Strong All Pakistan Marketing Networks & Brands.

- Strong Research & Testing facilities all over the country. Competitive Range of Pipeline Products in Major Fields and Vegetable Crops.

- Poised to play more significant roles in Agriculture Development, Farmer Prosperity and Promotion of indigenous Developed Agricultural Technologies.

- Very Good infrastructure for Product Development, Quality Assurance, Production and Processing.

- Irrigated land and Research Farms/laboratories all over the country.

- Four major R&D Sub Stations located in 4 major regions of the country.

- Highly qualified R&D Scientific and Technical Staff.

- Close co-operation with International and National Research institutes.

- Good relation with farming community, close contacts with progressive farmers.

RE-PROCESSING UNIT:

RE-PROCESSING UNIT:

The state of the art reprocessing plant of Ansons Foods uses 21st century technology from Buhler and China. The online inflow and outlow mechanisms are fully computerized with the help of sensors. The plants have production capacity exceeding 52 metric ton per hour. Adding up the total production of our mill is about 1250 metric ton per day. The firm is equipped with a number of pre-cleaners, de-stoners, precision sizers, graders, paddy separators, de-huskers, magnets etc. The plant premises are environment friendly and fully protected against contamination by foreign particles and covers total land of 4,00,000 square feet. A series of color sorters and multi sorters are installed at Ansons Foods. When the rice is passed through the series of sorting machines, it gets free from glass pieces, plastic, granules, foreign material, dust, damaged, discolored and unwanted grain.